Dolomite Powder Applications

Dolomite can be used for building materials, ceramics, glass and refractories, chemicals and agriculture, environmental protection, energy and other fields. After dolomite milling processing, the dolomite sand can be 6-10 mesh, 10-20 mesh, 20-40 mesh, 40-80 mesh, 80-120 mesh; dolomite after grinding mill processing, the dolomite ultrafine powders can be 140 mesh, 325 mesh, 600 mesh, 1000 mesh, 1600 mesh.

Dolomite is used as an ornamental stone, a concrete aggregate, a source of magnesium oxide and in the Pidgeon process for the production of magnesium. It is an important petroleum reservoir rock, and serves as the host rock for large strata-bound Mississippi Valley-Type (MVT) ore deposits of base metals such as lead, zinc, and copper. Where calcite limestone is uncommon or too costly, dolomite is sometimes used in its place as a flux for the smelting of iron and steel. Large quantities of processed dolomite are used in the production of float glass.

In horticulture, dolomite and dolomitic limestone are added to soils and soilless potting mixes as a pH buffer and as a magnesium source. Home and container gardening are common examples of this use.

How To Choose 1000 mesh Dolomite Micro Powder grinding mill:

Clirik Machinery devoted to provide Dolomite processing and grinding solution,The recommended Dolomite Powder grinding Machine is HGM micro powder milling machine, which meets client’s requirements of excellent fineness, reliable performance and favorable price.Clirik Dolomite Grinding Mill is mainly applied to non-inflammable, non-explosive and brittle materials with Mohs’ hardness under six. Such as Dolomite, chalk, Dolomite, dolomite, kaolin, talc, etc, totally more than 100 kinds of materials. Product fineness can be controlled between 325~3000 mesh.

If you want to processing Dolomite powder ,please choose the following plant:>> Coarse powder grinding mill: output size below 3mm, capacity 100t/h

>> YGM high pressure suspension grinding mill: output size between 15-425meshes

>> HGM three-ring micro powder milling machine: output size between 200-3000meshes (can be adjusted)

1. Application of 1000 mesh Dolomite micro powder grinding mill1000 mesh Dolomite powder grinding mill can not only process the Dolomite, but also for the medium and low hardness, superfine powder processing Mohs hardness of less than 7 of non flammable and explosive brittle materials, such as Dolomite, chalk, Dolomite, dolomite, silica, kaolin, bentonite, Dolomite, magnesite, talc, illite, vermiculite, sepiolite, pyrophyllite, attapulgite, rectorite, diatomite, barite, gypsum, alum stone, Dolomite, fluorite, phosphate rock and potassium ore, pumice and other 100 kinds of materials.

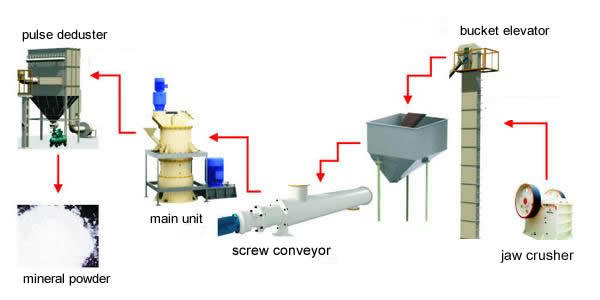

2. The structure of 1000 mesh Dolomite micro powder grinding millDolomite powder grinding machine full set of configuration consists of hammer crusher, bucket elevator, storage hopper, vibration feeder, grinding, grading machine, double frequency conversion main cyclone powder collector, high voltage pulse dust removal system, wind machine, air compressor, electric control system. According to the needs of the user can also be equipped with a broken machine, hoisting machine, storage hopper, electromagnetic vibration feeder and electric control cabinet and other auxiliary equipment, according to the requirements of users equipped with lifts, storage bin, electric control cabinet, electromagnetic powder feeder, crusher, milling equipment.

3. The working principle of the 1000 mesh Dolomite micro powder grinding millWhen working, the host of ultrafine grinding mill motor through reducer drives the spindle and the rotary table drive pin, and the edge of the dozens of roller in the rolling mill ring raceway.

Dolomite raw material by the hammer crusher into small particles by the elevator into the storage bin, again through the feed tube vibration feeder and the tilt of the disc, the bulk of Dolomite particles evenly to the upper part of the rotary table.

Effect of Dolomite powder dust under the centrifugal force to the circumference of scattered, and fall into the grinding roller is ring roll impact, rolling, grinding ring, three ring road after processing into the Dolomite powder, high pressure blower through the pumping action of the external air into the machine, and the crushed Dolomite powder with selected powder machine.

Selection of the rotation of the impeller powder machine make coarse Dolomite powder down heavy grinding, with fine powder with airflow into the cyclone powder collector and from the lower part of the discharge valve discharge is the Dolomite powder final, with a small amount of fine dust in the air and then through the pulse dust collector after purification by the blower and silencer discharge.

Learn more: http://www.dolomitegrindingmill.com/news/11.html

If you have any questions, please do not hesitate to contact us.

Phone: 0086-21-20236178 008613917147829

Contact person: Alice

Email: sales@clirik.com

related products:

Dolomite Powder Packing Machine